Fab antibody fragment titer improvement

Challenge

- A partner was developing a Fab fragment to quickly neutralize a therapeutic substrate

- Their E. coli platform generated low Fab titer and meaningful supply was needed for clinical development

- A cost effective process required titers >2 g/L

Solution

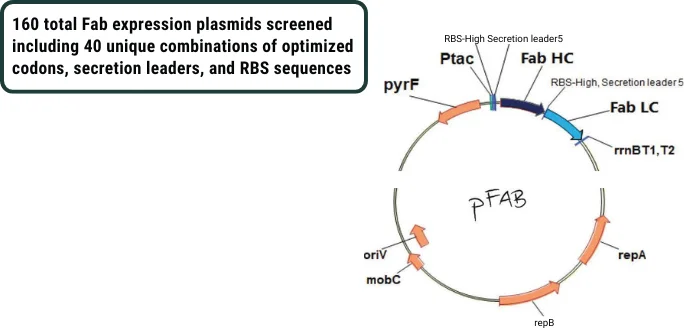

- Hundreds of toolbox strains screened at 96-well scale to identify optimized expression of assembled and active Fab

- Fermentation at 2L scale achieved Fab titers > 4 g/L

Key Results

- 2L fermentations produced assembled Fab over 96-hour induction time

- Active Fab titers from lysate >4 g/L (SDS-CGE and BLI)

SCREENING WORKFLOW

- 800 unique expression strains screened at 96-well scale

- Down-selected strains assessed at 2L scale for Fab titer under multiple induction conditions (pH, temp; induction OD, time, and inducer concentration)

- Fab enriched from selected fermentation pastes via affinity chromatography

- Enriched Fab quality assessed for intact mass

- >4g/L of active Fab produced

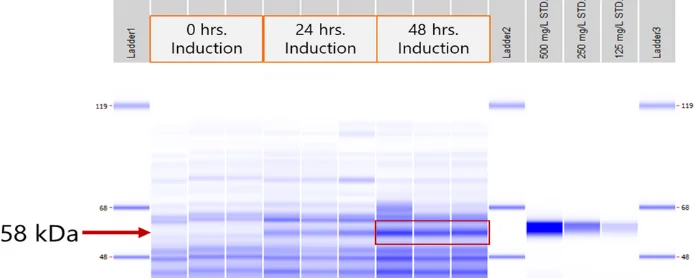

2L Fermentation Lysate Samples

One strain, one induction condition shown; triplicate analytical samples (0 – 48 hours post induction; SDS-CGE, non-reduced)